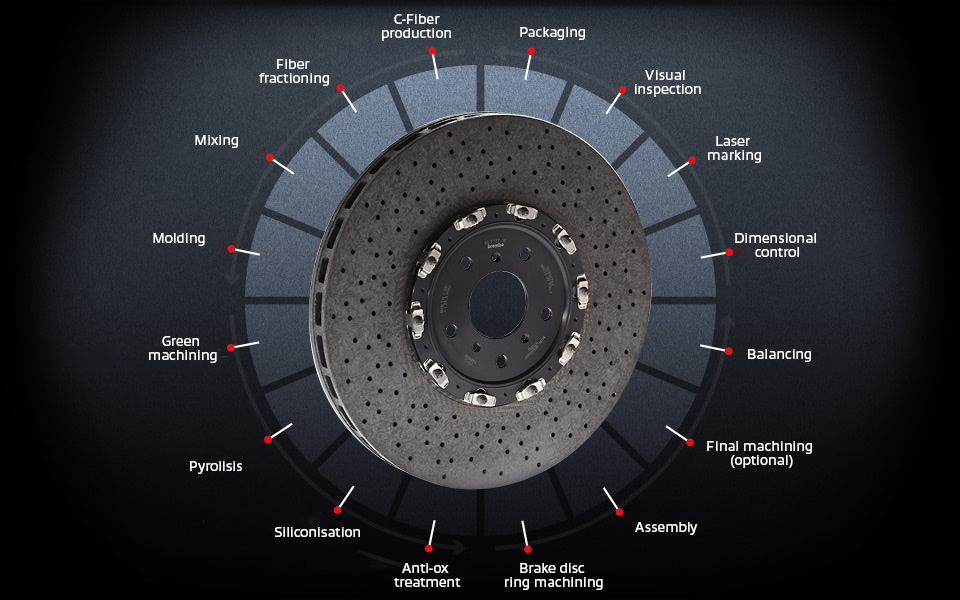

The carbon-ceramic brake disc has a production process over approximately 20 days.

To produce carbon-ceramic-brake discs, we use carbon fibers which are given a special protective coating and then cut into short fiber sections of defined thickness and length. The fiber can be used directly or can be treated in order to obtain a complex row material called “carbochip”. The production process starts with a mixture of the component and ends with the assembling of the rotor and the bell. The production process of the ceramic brake body requires a preform pressed with binding resin to a so called green body which will be converted in the ceramic component by first carbonizing at 900 °C and second by liquid silicon infiltration (siliconization) at 1700 °C in vacuum athmosphere.

One of the complex features of the manufacturing process is the use of the “lost core“ technology – a plastics matrix which defines the design of the cooling channel geometry and which burns out without residues at carbonizing. Another complex feature is the use of different fiber components of the brake disc body, the friction layers on the ring exterior side and the point-shaped abrasion indicators which are integrated into the friction layer. The final machining also require high technology because the hardness of the material force the use of diamond tools.

Production process phases